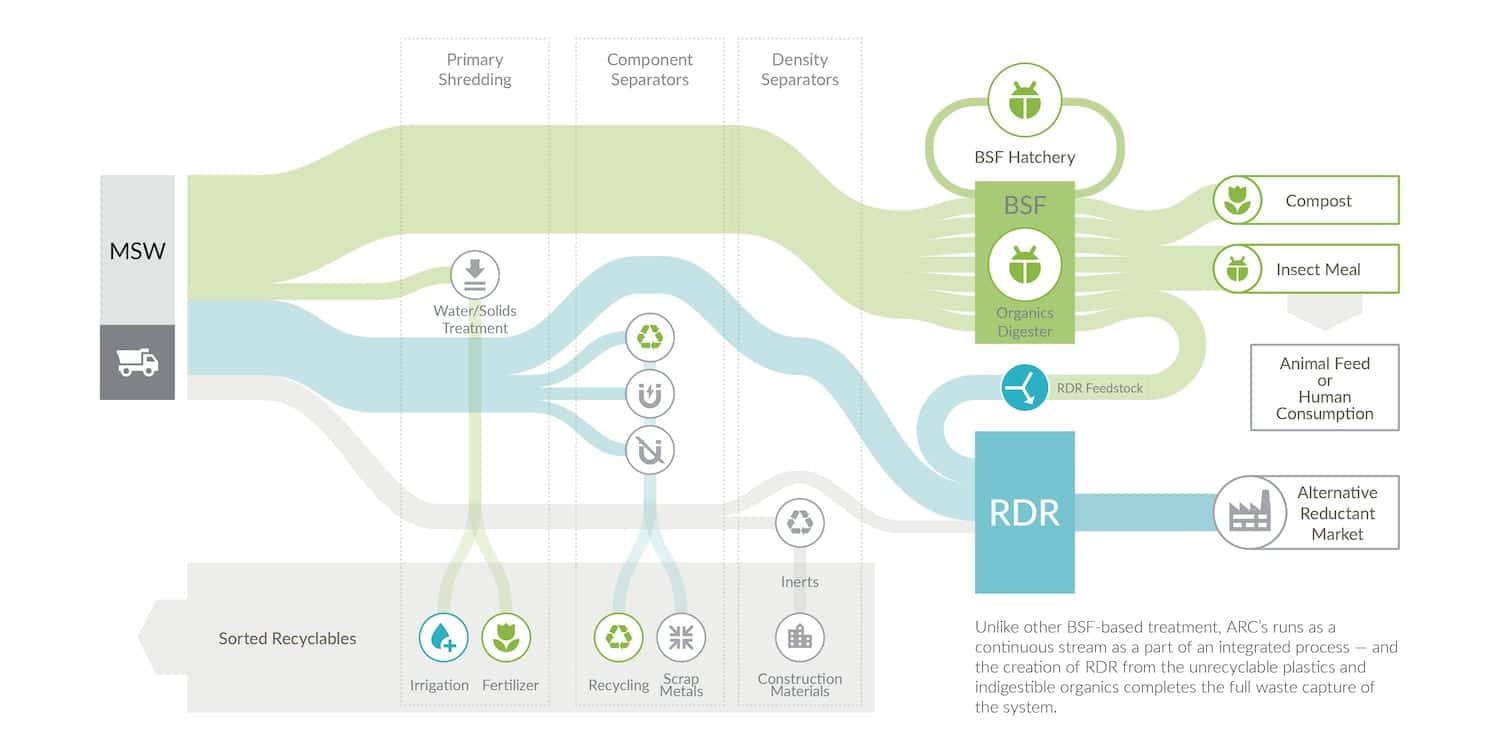

The ARC Process is a continuous series of mechanical and bio-mechanical processes that convert more than 70% of MSW into five marketable commodities:

· high nutrient compost

· high grade meal for aquaculture

· ferrous metals

· non-ferrous metals

· an innovative industrial reductant which can replace coking coal

The ARC Process is patent-pending and incorporates two technologies which serve as the heart of the system:

· the first is the use of black soldier fly larvae to consume all digestible organics in the MSW, converting them to highly marketable insect meal and nutrient-rich compost

· the second is the conversion of non-digestible organics such as plastics and cardboard into a valuable industrial use product, Refuse Derived Reductant™ (RDR) .

The process is initiated by screening and shredding incoming MSW using magnetic separators remove ferrous metals from the waste stream, followed by eddy current separators to recover non-ferrous metals. These metal products are then sorted for their salvage quality, and high-quality salvage is sold and shipped to buyers.

Our unique, patent pending process produces five MSW-derived

products.

The never-ending supply of MSW produced by

modern society assures a steady supply of our products while

insulating our production costs from virgin material price

fluctuations. Reliable supply, coupled with our rigorous quality

control program for ARCsoil, ARCmeal and RDR, assures the

quality and consistency of our products.

Innovative Technology

BSF Digester

The next step involves our proprietary Black Soldier Fly (BSF)

Digester where BSF larvae convert the 30% of MSW that is food

and other highly digestible organic waste into high-quality

compost and aquaculture and animal feed.

Our BSF

digester utilizes the voracity of BSF larvae to consume a wide

variety of organics. They are ideal for the innovative,

continuous process of the ARC Digester and they enable the

decomposition rate to match the rate at which organic waste is

introduced into the digester, whereas organisms, such as

earthworms, cannot match the rates of BSF larvae.

Accelerated

decomposition due to the patent pending design of the ARC

Digester creates a critical advantage by enabling the system to

efficiently handle all organics. The bio-products produced are

harvested and segregated to produce commercial products - insect

meal and organic compost fertilizer. System efficiency is

supplemented by the fact that indigestible organics (such as

wood, rubber and leather) move on to RDR processing into

commercial products.

hermetia illucens

The Black Soldier Fly

Nature’s Efficient Waste Processor

To process organic waste ARC’s solution draws on the

special capabilities of the black soldier fly (BSF) to provide a

sustainable and commercially viable process.

The

Black Soldier Fly Hermetia illucens is a true fly of the family

Stratiomyidae. Though originally native to the Americas, it now

occurs worldwide in tropical and temperate regions. Adults

consume nothing but water, do not approach humans, do not bite

or sting, and do not vector or disseminate any specific

diseases. BSF larvae feed on an immense variety of organic

material and have been described as “not picky eaters”.

They

are already used in small-scale waste management to process

manure, rice straw, food waste, distillers’ grains, fecal

sludge, animal offal, and kitchen waste and other organics. BSF

larvae may be the most efficient waste processors among the

flies and their feed conversion ratios are known to be superior

to both crickets and mealworms. BSF larvae are also edible and

are used as animal feed and can be consumed by humans (tastes

permitting). They accumulate sufficient lipids to provide energy

for the non-feeding adult to the point where they can be

converted into biodiesel. What they do not consume, combined

with their nitrogen-rich frass, can be used as fertilizer.

Their

three week larval stage is longer than that of house and carrion

flies (at less than 5 days) which means a single BSF larva will

consume a larger amount of substrate and produce larger pupae.

When BSF larvae are at the pre-pupa stage, they instinctively

leave the substrate and move to a high, clean place - a behavior

called “self-harvesting” - which removes an otherwise

labor-intensive step from their farming.

All these

benefits make the larvae of the Black Soldier Fly a highly

practical organism to process organic wastes and serve as a

sustainable animal, and possibly human, food source.

Innovative Technology

Refuse Derived Reductant™

Unique to the ARC Process™ is our patent-pending technology for

isolating and processing plastics and other non-digestible

organics into Refuse-Derived Reductant. Our RDR product is a

dense solid that has a high carbon content, few impurities and

an energy density approaching that of anthracite coal. As such,

it is a low-cost alternative to the use of high-grade coal or

coke in industrial applications such as smelting or the

manufacture of steel or other processes that require the use of

a highly efficient fuel or reducing agent.

Our RDR

process first passes plastics and other non-digestible organics

through a drying and semi-pyrolysing process to remove excess

moisture and start charcolising the organics. The process is

temperature controlled to maintain product quality and

consistency and the softened plastic is then put through a

plastic extruder to be formed into RDR briquets and dried. The

high density of the briquets facilitates handling and shipment

and makes them applicable to a wider range of industrial

applications.

Our innovative, efficient process

holds the promise to reduce MSW waste going to landfill by more

than 70% and ultimately close to zero, and possibly zero.

ARC’s

comprehensive approach is the strength of our system and we are

unaware of any other similar commercial process in the MSW

field.